Heavy industry and the net-zero economy

Using a range of technologies can help to cut industrial emissions, and save money.

By Jess Ralston

@jessralston2Share

Last updated:

Current emissions and energy use

About half of industrial emissions can be eliminated through a wider economy shift from fossil fuel use to clean energy. Generating all electricity from zero-carbon sources will eliminate grid-linked CO2 emissions.

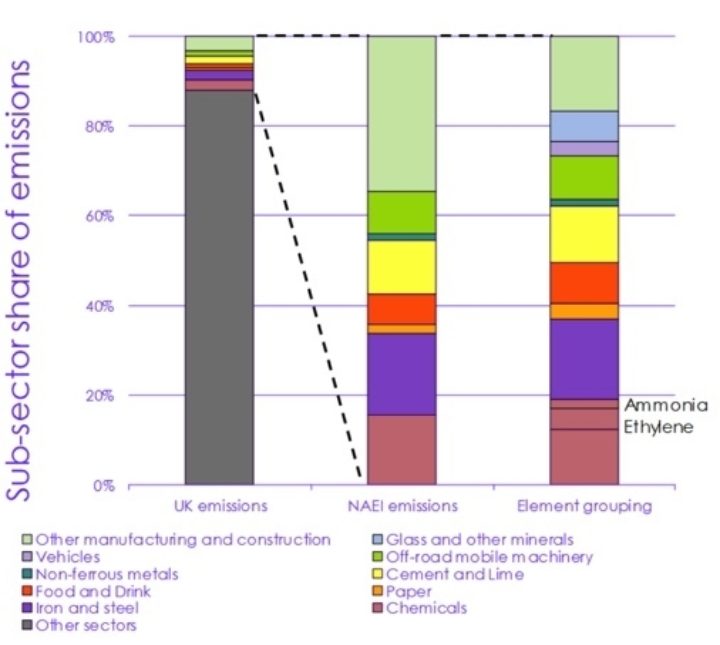

Producing and refining oil and gas leads to 40% of direct industrial emissions. Ending their use as an energy source will substantially reduce this, as they will only be needed for industrial applications such as making plastics.

The remaining 60% of direct industrial emissions comes from manufacturing. Here we look at four of the main industrial emitters – steel, cement, chemicals and aluminium.

Steel

Iron and steel account for 18% of UK industrial emissions. There are huge opportunities to reduce this on both the supply and demand sides.

All future growth in demand for UK steel could be met through recycling. Recycled steel is made using electric arc furnaces – which produce no carbon emissions if the electricity comes from renewables or nuclear. By contrast, making virgin steel uses iron ore mixed with coal.

Careful disassembly of old products to separate steel from other metals means it can be upcycled into higher-value products; the volume of steel available for recycling will treble in the next 30-40 years.

Cleaning up virgin steel production is also possible. Replacing sinter, the form in which iron ore is fed into the blast furnace, with pellets could reduce CO2 emissions significantly. Additionally, a Swedish consortium is trialling the use of hydrogen to replace coal. There’s more on hydrogen for industry in this ECIU briefing.

Cement

Cement and lime contribute about 12% of direct UK industrial emissions. The industry has already cut emissions by more than 55% since 1990, and has analysed how to reduce them by 81% by 2050.

More than half of emissions come from the process of producing clinker, the main ingredient in cement, from ingredients such as calcium, silicon and iron. Reducing clinker content by 70% is feasible, and could save about three-fifths of projected cement emissions globally in 2050 at very little cost.

The process of producing clinker itself can also be made cleaner by using ingredients such as graphene, and by substituting the fossil fuels – mainly coal – used to power cement kilns. Improving energy efficiency would also curb emissions – European and US cement plants are less efficient than those in China and India.

A more radical solution is carbon-negative concrete, which absorbs more carbon dioxide during hardening than is released during production. A number of companies are close to bringing a product to the market.

Using higher quality concretes, alternative building materials and being more efficient on-site could reduce demand and hence emissions by more than 50%. Partially hollow structures could possibly reduce concrete use by 70% without compromising structural integrity.

Chemicals

The chemicals industry contributes about 16% of UK industry's direct emissions. It produces a wide range of substances – therefore there is not a ‘one-size-fits-all’ solution.

Improving efficiency is relevant across the sector. The process that consumes the most energy is steam cracking to produce light olefins, one of the two main petrochemical groups. Upgrading to the best available technology could reduce energy intensity by almost a quarter.

For some end-products a big opportunity is bio-processing, which uses biological systems to make products. However, this is currently expensive, and there are concerns about availability of the biological materials. Separating chemicals with membranes rather than distillation and heating would also reduce emissions while saving companies money.

Aluminium

Aluminium accounts for about 1% of global GHG emissions. However, with just one production site in the UK, its contribution to UK emissions is small at 0.1% of total CO2 emissions. On average, 70% of emissions associated with virgin aluminium production are from electricity, which can be reduced by using low-carbon supplies.

The biggest process emissions come from the electrodes used in smelting. They are made of carbon and give off CO2 as they wear down. Industrial giants Alcoa and Rio Tinto have developed a replacement material that releases oxygen instead. They estimate it will be commercially available in 2024.

Carbon capture and storage

Possibly the technology with the biggest potential to reduce emissions across industry is carbon capture and storage (CCS).

Here, the CO2 is captured before entering the atmosphere and stored underground. Alternatively, it can be used to make fuel, plastic or chemicals (carbon capture and utilisation, or CCU). Most research and development has been in the power sector, but industry is catching up.

Following a successful trial, work is underway in Norway on the world’s first full-scale cement carbon capture plant. Work has also begun on a next-generation technique where CO2 is separated and captured at source, known as process-integrated carbon capture. This should prove much more cost effective.

In the UK, the Government announced £1bn of funding for CCS projects in 2020 to develop operational CCUS in four industrial clusters by the end of the decade. It’s estimated that this could support 50,000 jobs. Front runners for this funding include Net Zero Teeside and a pipeline connecting biomass burners at Drax and industry in Humberside.

The potential

The Climate Change Committee’s 6th Carbon Budget report indicates that UK industrial CO2 emissions could be reduced by up to around half by 2050 using measures that exist today, such as resource and energy efficiency, material substitution and electrification. The rest of the emissions reductions, down to residual emissions of just 3MtCO2e (down from 66MtCO2e in 2018) , comes from technologies like hydrogen, CCS and biofuels that are yet to be completely developed to the scale needed in 2050.

To support these more emerging technologies, the Government is expected to release a new Industrial Decarbonisation Strategy in the first half of 2021. This strategy should provide a route map to a decarbonised industrial sector and support private investment from industry.