Industry and emissions (globally and UK)

What progress has been made on reducing emissions from industry, and what options are available?

By Jess Ralston

@jessralston2Share

Last updated:

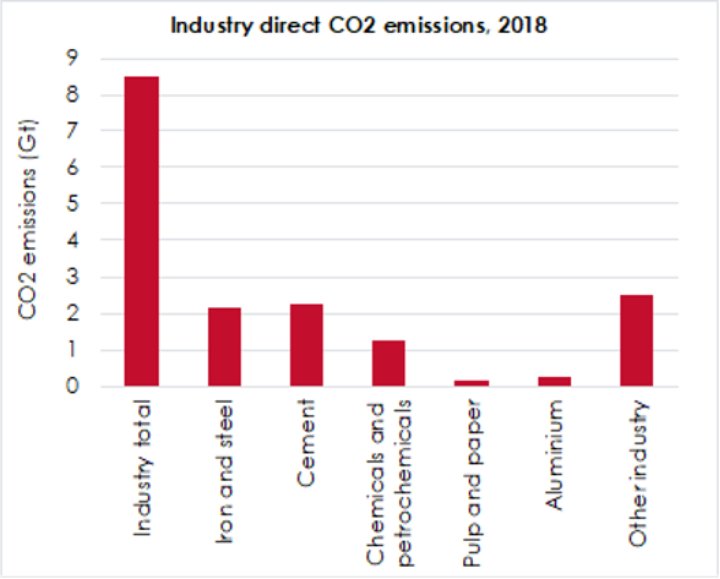

Industry is responsible for around a quarter (23%) of global emissions, meaning that along with transport (also 23%), it has the second-highest sectoral emissions behind energy generation systems. Within industry worldwide, cement manufacturing is the largest emitter, followed by iron and steel production and then petrochemicals.

In the UK, industry is responsible for a lesser proportion of emissions at 12%, reflecting that the UK has moved from a secondary economy (manufacturing) to a tertiary and services economy, and has reduced its industrial emissions by 56% on 1990 levels. This economic shift primarily took place in the 1990s and 2000s and before climate change featured on the national agenda. Of this, iron and steel and chemicals were the major emitting subsectors. In 2021, the UK Government set out goals to cut emissions from industry by two-thirds by 2035 and by 90% by 2050.

Countries and country blocs with a large manufacturing and industry economy, such as China (28%), the US (17%), Japan (7%) and Germany (6%) make up over half of all of the manufacturing output in the world. While all of these countries are producing low carbon goods, like electric vehicles, as well as converting some of their processes to emit less carbon, a significant proportion of their industrial processes – which often rely on high temperatures to carry out reactions or activities – remain a barrier to decarbonisation.

However, not all emissions due to UK activities are counted as UK territorial emissions – some are ‘extra-territorial’ and are counted as belonging to other countries instead. For example, some of the products we import and use are made in industries abroad so the emissions fall into the remit of the manufacturing country rather than the UK’s. This is known as exported emissions or ‘carbon leakage’.

Options for reducing emissions from industry include resource and equipment efficiency, limiting the amount of energy required by minimising waste and recycling. For complete decarbonisation however, alternative fuels to fossil fuels used today are likely to be needed, like hydrogen (which can be made in a ‘green’ way), as well as electrifying some industrial processes (such as glassmaking).

Steel

Steel is responsible for around a quarter of global industrial emissions and around 8% of total global emissions. This is because it requires high temperatures (today generated by burning fossil fuels) and uses coal within the reaction that makes the metal. Although the transition to green steel is underway in some countries, such as Sweden , in most other nations it is in its beginning stages. Electric furnaces (which melt the raw materials) could also be used instead of ones running on fossil fuels.

The UK’s steel industry, mainly in South Wales and on the Humber, produces about a fifth of the UK’s emissions from industry and 3% of the UK’s total CO2 emissions. The sector employs over 70,000 highly skilled people and contributed £2bn to Gross Value Added (GVA) in 2018.

Although the Government announced a Clean Steel Fund in 2019, this has yet to be fleshed out in any detail, including within the Industrial Decarbonisation Strategy which was published in early 2021. Recent analysis evidences that the race to clean steel has begun - there are 23 hydrogen-based green steel projects underway in Europe compared to none in the UK. More broadly, the Industrial Decarbonisation Strategy was criticised for having little new spending or policy in it, resulting in some still questioning how the UK will decarbonise its heavy industry.

There is currently some controversy around the UK Government considering opening a new coal mine in Whitehaven in the North West to produce coking coal - the type used in steel manufacturing. Some experts have condemned this move as hypocritical, and the Prime Minister recently confirmed that the Government does ‘not want to support new coal mines’. A final decision on the mine is expected in 2022.

Other manufacturing

Cement, used largely to produce concrete, is responsible for around a tenth of the UK’s industrial emissions and 2% of the UK’s total emissions. Globally, it’s thought that cement manufacturing could be responsible for over a quarter (26%) of industrial emissions and 8% of total carbon emissions.

Over half of cement emissions are related to the production of clinker, a mixture of limestone and clay which binds the cement together. The chemical reaction to produce clinker creates CO2 as a direct by-product, making it difficult to decarbonise. The majority of the remaining emissions result from powering high temperature kilns by burning fossil fuels. If these are switched to run on cleaner electricity, emissions could be reduced.

A high proportion of chemicals manufacturing relies on petroleum, as both a source of base material and also for fuel during processing. While the oil and petrochemical industries are expecting demand for their products to rise, others are more cautious, warning that plastic demand will peak by 2027 and the transition to a circular economy will mean that the industry will ‘lose its primary growth driver’.

In the UK, the chemicals industry produces around 15% of the UK’s industrial emissions and over 2% of its total CO2 emissions, with £19.2 billion GVA added and around half a million jobs depending on this industry in 2018. The largest chemical production hub is in the North West of England, where it’s worth £10 billion. Like steel, one option to reduce chemicals emissions could be to use hydrogen as an energy source for chemical production, instead of natural gas. The HyNet project in Merseyside is looking at making this switch, backed by £72m funding. However, given some chemicals and plastics are made from petroleum products, it will likely be hard to move away from fossil fuels entirely in the short to medium term.

Demand side response

Industrial processes across the world can also play a role in storage and flexibility of the energy system. Demand side response (DSR) contracts – where energy intensive users sign a contract to flex when they do or don’t use energy in return for payment – can help to balance the grid. This is used extensively in some countries already, like the US, and it is thought that the UK will likely carry out more DSR as increasing amounts of renewables are used to generate power.