Hydrogen for heating

How can hydrogen be used to heat our homes in a low carbon way?

By Jess Ralston

@jessralston2Share

Last updated:

In the UK, the gas grid provides energy to more than 80% of homes. However, this has not always been the case. During the 1960s and 70s - to capitalise on hydrocarbons from the North Sea – the entire gas grid was switched from a mix of gases released from burning coal, known as ‘town gas’, to the natural gas that is still used today.

This previous conversion of the gas grid provides an argument in favour of doing it again, and to claims that it would be less disruptive than changing to other sources of heat.

However, the national gas grid would need to be repurposed to deliver hydrogen, while home boilers and other gas-fuelled appliances would need to be adapted or replaced, although both of these processes are thought to be achievable in the long term. The benefit to this technology is that it requires little behavioural change on the part of the homeowner – new heating system would operate in the same way as those installed today.

How is hydrogen made?

Current commercial production of ‘blue’ hydrogen through steam methane reformation is very energy intensive and creates large amounts of CO2 as a by-product (10–12 kgCO2e per kg hydrogen).

To avoid hydrogen production becoming a new major source of emissions, it would have to be developed in conjunction with carbon capture and storage (CCS). CCS has yet to be developed at scale in the UK – the first commercial CCS plant is not expected until the mid-2020s - although there is clear potential for high levels of CCS..

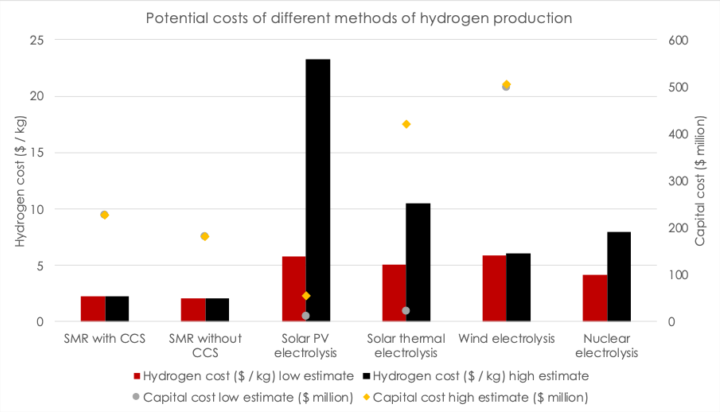

Another method of production uses electrolysis to split water into hydrogen and oxygen. Assuming low carbon electricity the electricity is used, the process can be zero-carbon. It is, however, more expensive – at the lowest estimate, over 150% more expensive in some cases (see figure 1). Hydrogen made in this way is known as ‘green’ hydrogen.

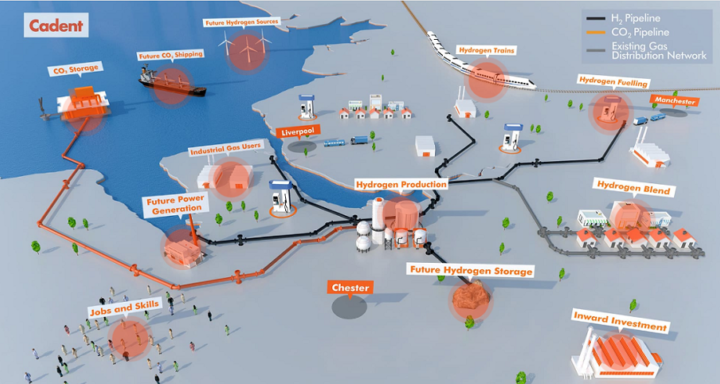

Plans for hydrogen production in the UK were given a £28 million Government boost in 2020, as plants in Merseyside and Aberdeenshire are thought to be able to cut the costs of hydrogen by 20% and others seek to prove that green hydrogen and CCS for blue hydrogen are viable.

In January 2021, it was announced that Essar (an oil refiner) and Progressive Energy will 'invest £750m to produce hydrogen for industrial users and potentially transport, heating and power generation' near Cheshire. The project will produce hydrogen using fossil fuels, capture the carbon emitted and store it in underground reservoirs off the coast of Liverpool, where there are already existing pipes to do so, left from infrastructure needed to extraction resources from there.

In addition, companies have invested heavily in hydrogen development and trials, some of which are seen as promising – shares in hydrogen producers reached decade highs in 2020.

These producers, mainly interested in converting the gas grid, have matched the investments of the Government as they seek to progress to net zero investments. This includes development of a hydrogen boiler from Worcester Bosch, leading gas boiler manufacturer, and testing the feasibility of this technology themselves.

This being said, the Committee on Climate Change (CCC) estimates that the deployment of hydrogen will be more likely in the 2030s and 2040s. It may also be better suited as a low-carbon transport fuel for heavy goods vehicles and shipping, rather than for domestic heat.

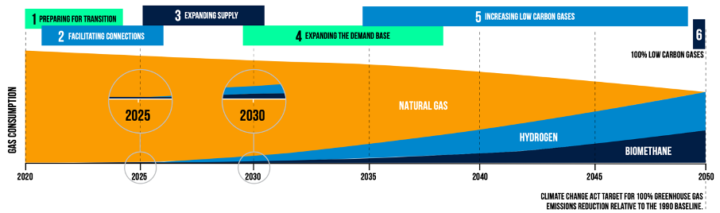

The Energy Networks Association (ENA) has set out a pathway to 2050. It suggests a combination of low carbon and renewable gases, alongside electrification, CCS and energy efficiency will be key to unlocking net zero.

With hydrogen production expected to ramp up from 2025 to 2050, biomethane will also be another significant low carbon gas pumped into the grid at scale during the 2040s. Together, hydrogen and biomethane are thought to be able to provide 100% of gas demand by 2050 (figure 3).

Cost

Best estimates of the costs of repurposing and running the gas grid on hydrogen are around £130 billion for converting the grid and £36 billion annual running costs, but different studies estimate higher costs depending on the various methods of hydrogen production.

It is very likely that hydrogen will play some part in decarbonising Britain’s heat supply. However, many experts agree that it is likely a combination of approaches will be needed to decarbonise heating at the scale needed to reach net-zero by 2050; there is not a one-size-fits-all solution.